Production

Polyurethane Panel(PUR/PIR)

KOR

Best Insulation Effects

With an innovative thermal conductivity of 0.020 W/m·k, the Urethane Panel is much better insulated than the Glasswool or the Schiphol, which reduces heating costs incomparable to conventional building materials.Excellent Flame Retardancy

The PIR panel using Polyisocyanurate Foam as an inner material improves flame retardancy and heat resistance while maintaining the advantages of existing polyurethane such as insulation performance, condensation prevention effect, and high strength rigidity.Low Hygroscopicity

It is formed of a hard closed cell structure and is resistant to water or water vapor, so the insulation effect does not change over time. It also has excellent stability and little contraction or expansion at low temperatures, so it is applied to refrigeration and low temperature warehouses for excellent performance.Easy Construction and Affordability

It are a solid building material that perfectly combines with a strong self-standing structure, making it easy to assemble and shorten the construction period, making it economical.It is an eco-friendly building material with the best insulation and condensation prevention effect as a panel made of urethane with the greatest thermal conductivity (0.020W/m·k).

The beaver urethane panel is the most effective building material for energy conservation and is suitable for building differentiated designs

with different types of panels to meet the needs of new building materials, specialization, and diversification customers.

The beaver urethane panel has a system that is light in weight and standardized, making it easy to assemble and construct, and shortening the construction period, saving construction costs. It is applied for various purposes and shows the highest value.

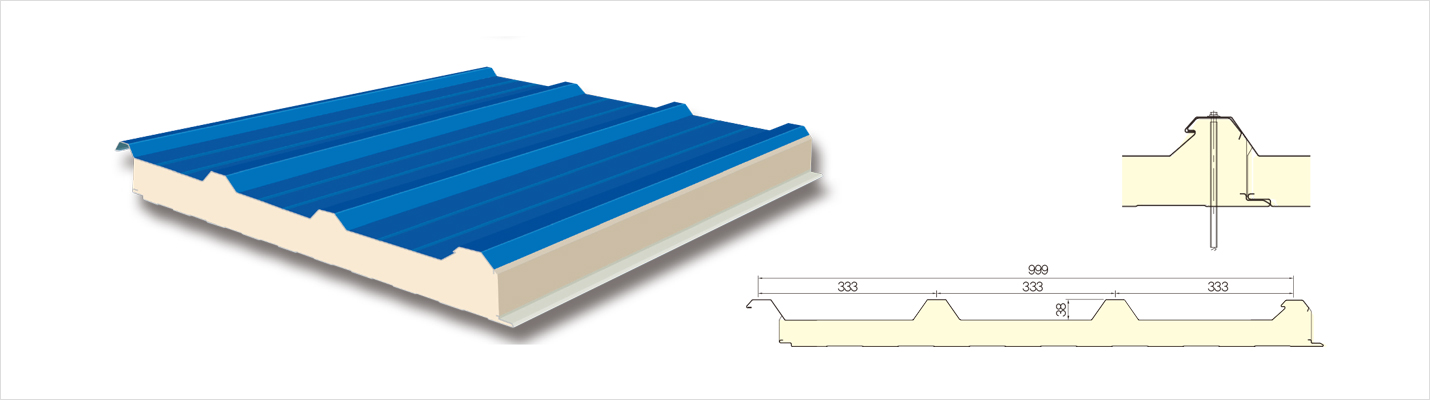

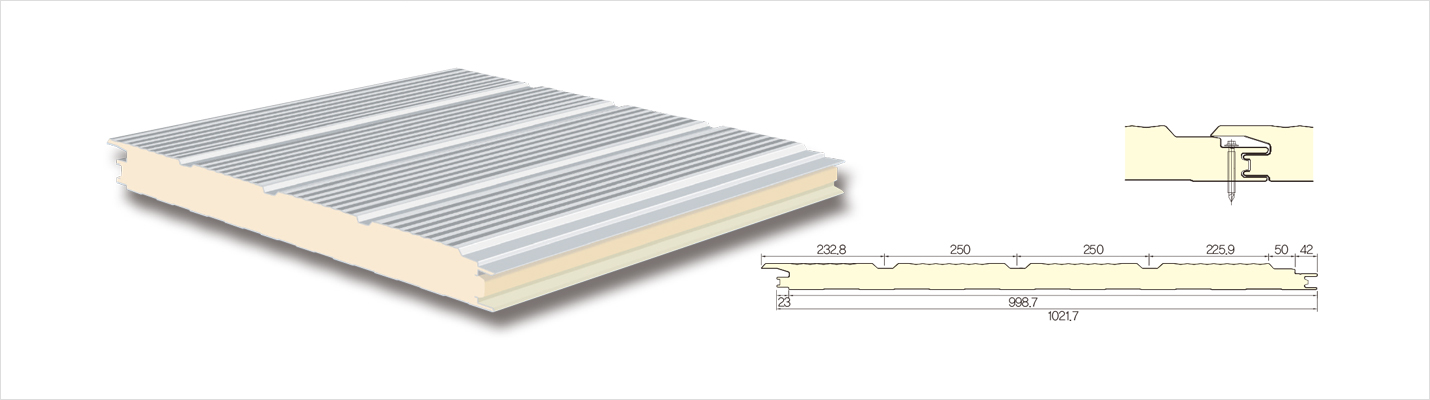

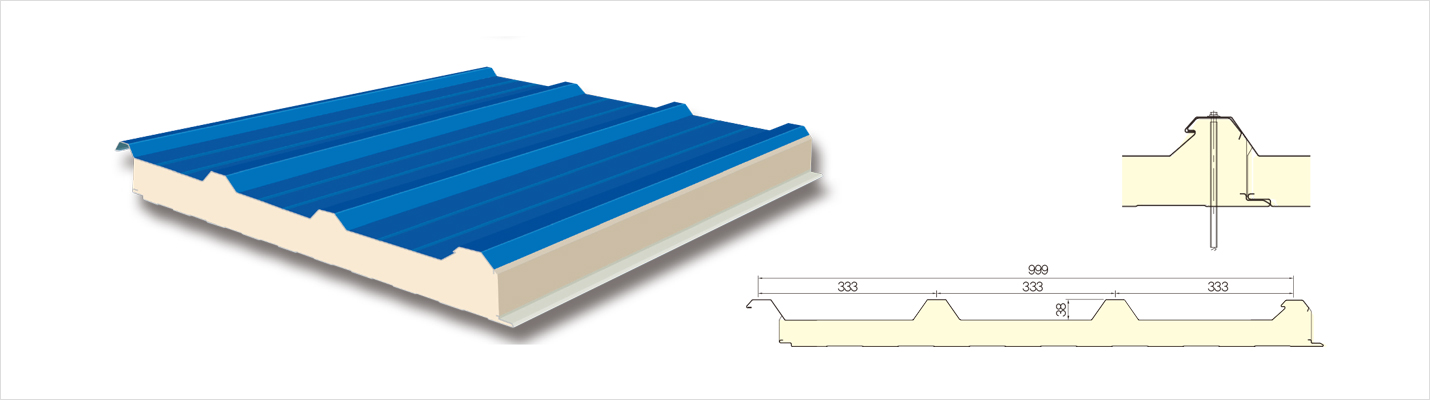

1. Hook and coupling structure strengthens the adhesion between panels

2. Prevention of breakaway in rainy weather accompanied by strong winds and blocking the inflow of rainwater

3. Perfect combination can be confirmed with the sound of 'click' when it’s combining the panel

Urethane panels have a uniform CELL structure that is excellent in insulation and anti-condensation, reducing waste of energy. They have excellent stability and have little contraction and expansion, especially at low temperatures, so they are applied to refrigeration and low-temperature warehouses.

| Test Item | Reference Value | Results |

|---|---|---|

| Density(kg/m3) | 35 or more | 43 |

| Thermal conductivity(W/m.K) | 0.023 or less | 0.019 ~ 0.023 |

| Flexural fracture load(N/cm2) | 25 or more | 56 |

| Compression strength(N/cm2) | 10 or more | 23 |

| Absorption amount(g/100cm2) | 3.0 or less | 0.2 |

| Descriptions | Specifications | |

|---|---|---|

| Material | Top Material | 0.5–0.8 mm Painting Melting 55% Aluminum zinc alloy plated steel sheet |

| Core material | PIR density : 43kg/m3 or more Thermal conductivity: 0.019 to 0.023 W/m·K | |

| Bottom skin material | 0.5–0.8 mm painting melts 55% aluminum zinc alloy plated steel sheet | |

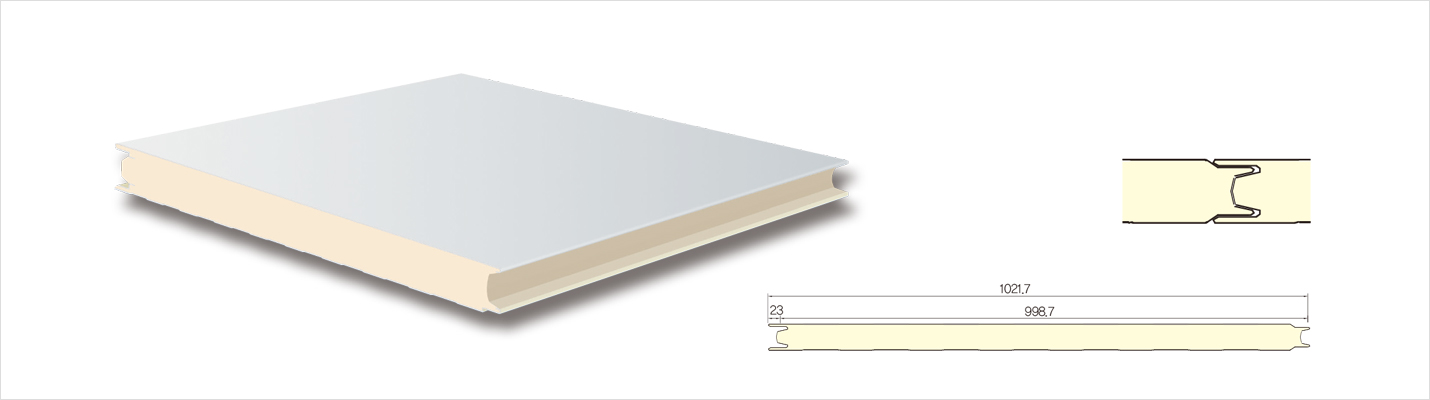

| Division | Effective width (mm) | 1,000 |

| Length(mm) | Transportable | |

| Thickness(mm) | Wall : 40, 50, 75, 100, 125, 150 / roofs : 50, 75, 100, 125, 150 | |

Beaver Panel is confident that the urethane panel produced by us, which has devoted itself to the development of prefabricated architectural culture and the creation of new architectural culture since its foundation, is of the highest quality.